Progetti aperti e disponibili senza vincoli

Montaggio e facile installazione (IKEA model)

Dati immediatamente disponibili ovunque

Costi accessibili ed elevati standard professionali

Configurazione

Altezza di precipitazione

Pluviometro a bascula in acciaio

Batteria 12V, 12Ah

Pannello solare

GPRS

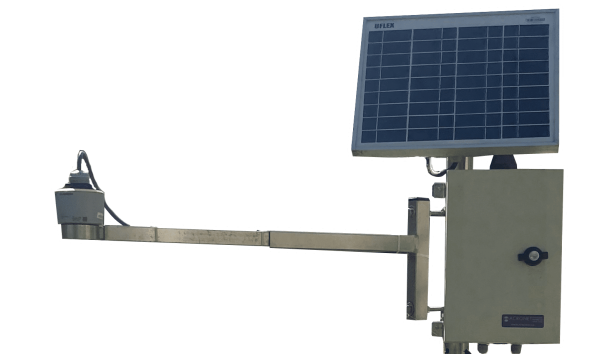

Configurazione

Livello idrometrico

Idrometro RADAR

Batteria 12V, 12Ah

Pannello solare

GPRS

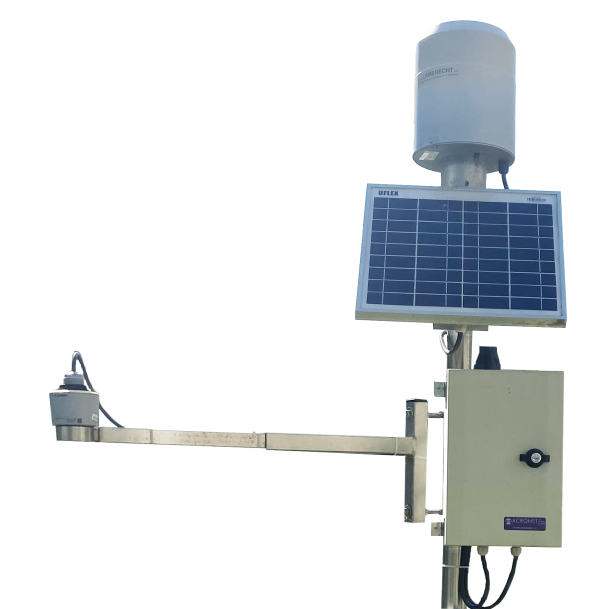

Configurazione

Altezza di precipitazione

Livello idrometrico

Pluviometro a bascula in acciaio

Idrometro RADAR

Batteria 12V, 12Ah

Pannello solare

GPRS

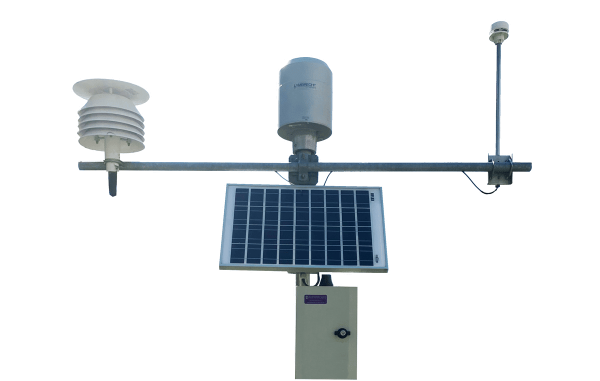

Configurazione

Altezza di precipitazione

Direzione e velocità del vento

Pressione atmosferica

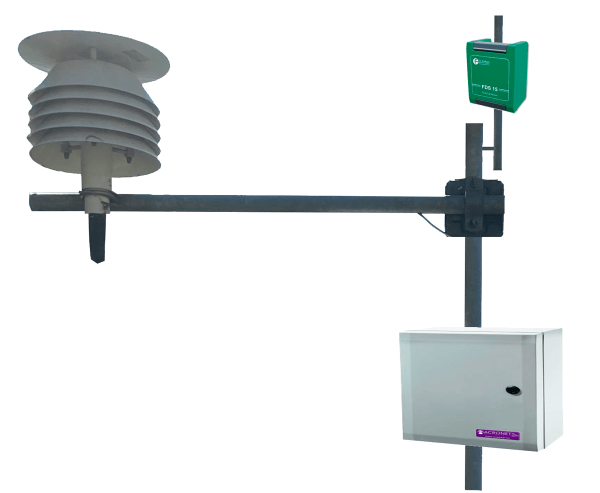

Temperatura e umidità dell'aria

Pluviometro a bascula in acciaio

Batteria 12V, 12Ah

Pannello solare

GPRS

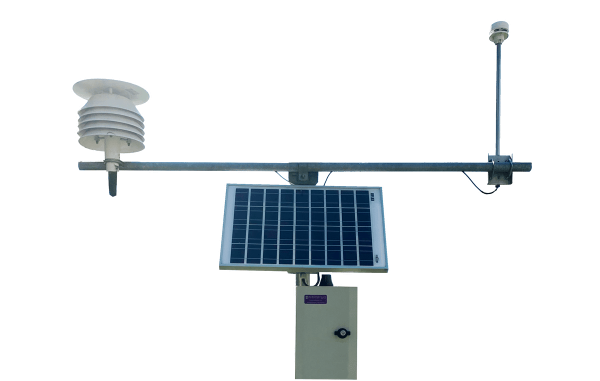

Configurazione

Direzione e velocità del vento

Pressione atmosferica

Temperatura e umidità dell'aria

Batteria 12V, 12Ah

Pannello solare

GPRS

GPS Tracking

Configurazione

Pannello semaforico segnalazione stati di allerta e allarme

Batteria 12V, 12Ah

Rete elettrica 18-24V 60W

GPRS

Configurazione

Polveri frazione PM10

Concentrazione NO2

Temperatura e umidità dell'aria

Batteria 12V, 12Ah

Rete elettrica 18-24V 60W

GPRS

I dati delle stazioni sono sempre disponibili in real time su ACRONETWORK.ORG

Registrandoti sul sito, potrai ricevere notifiche via mail o SMS riguardanti soglie d’allarme o di allerta. Inoltre, potrai interagire con le stazioni interrogandole grazie al bot Telegram @AcronetBot